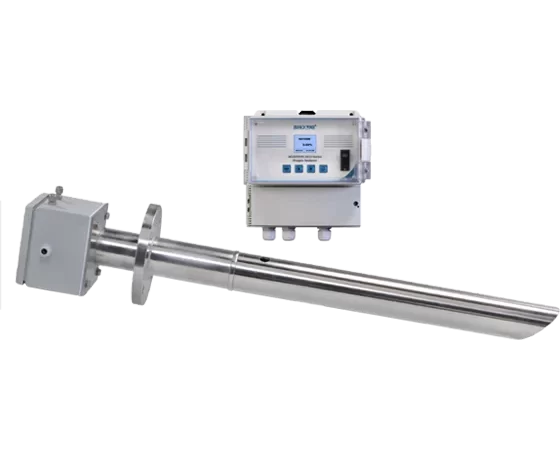

5 things to know about Agasthya 2013 Series Insitu Zirconia Oxygen Analyzer BI 2100-S

Oxygen analyzers are used in various industrial combustion processes to detect the concentration of oxygen in a mixture of gasses. Zirconia oxygen analyzers use a zirconia sensor to pick up the oxygen concentration. When exposed to a gas sample, the zirconia sensor generates a voltage proportional to the oxygen partial pressure difference across its surfaces. This voltage is then converted into an oxygen concentration reading.

Here, we share 5 things you must know about Agasthya 2013 Series Insitu Zirconia Oxygen Analyzer BI 2100-S (up to 700 deg C).

- General information:

The Agasthya 2013 Series Insitu Zirconia Oxygen Analyzer BI 2100-S (up to 700 deg C) is a specialized device that can help with emission monitoring and with the optimization of combustion operations in industrial environments. The machine can accurately determine the amount of excess oxygen in flue gasses. To ensure the best combustion efficiency, it is vital to maintain proper levels of oxygen in flue gas.

The oxygen analyzer can be customized to match different site conditions and optimize them for diverse processes. Also, it offers a cost-effective solution for detecting oxygen levels. The analyzer has no moving parts, which means it is highly reliable and not prone to failure. - Features:

– The analyzer features a Zirconia sensor, which can last for 4 to 5 years.

– The device offers minimal drift or negligible drift of <0.5% of FS

– High Accuracy of ±0.5% of FS offering accurate results

– Response Time of T90<3 sec gives faster response enabling operator to take quick action.

– It has a one point calibration system

– Because there are no moving parts, the analyzer requires almost no maintenance over its lifespan.

– It has to often operate under high temperature conditions. To ensure proper functionality in such settings, its thermal shock proof – nature can be handy.

– The device is extremely easy to repair while it is employed on the field, which means minimal downtimes. - Insitu Oxygen Sensor Specification:

Range: The range is between 0 and 100% and it can be programmed as needed.

Accuracy: ±0.5% of FS

Resolution: 0.01%

Repeatability: ±0.5% of FS

Response Time: T90< 3 sec

Process Gas Temperature: 0 -700° C - O2 Electronic Unit Specification

Power: 24 VDC. 230 V AC

Display: Keypad LCD Display

Digital interface: RS 485, Modbus protocol

Output: 4-20 mA Analog Output - Applications:

This particular oxygen analyzer is used in different industrial operations. These include –

Iron and steel furnaces

Boilers

Brick, glass and cement furnaces or kiln

Petroleum refining

Looking for a zirconia gas analyzer?

Explore our Zirconia oxygen analyzer collection. Besides the Agasthya 2013 Series Insitu Zirconia Oxygen Analyzer BI 2100-S (up to 700 deg C), we also have other options for different industries and temperatures. For instance, the Agasthya 2013 Series Insitu Zirconia Oxygen Analyzer BI 2100-HL can handle processes ranging in temperatures up to 900 degree Celcius and the Agasthya 2013 Series Insitu Zirconia Oxygen Analyzer BI 2100-HH can handle processes ranging in temperatures up to 1600 degree Celcius