Application – Aluminum Industry

Aluminum

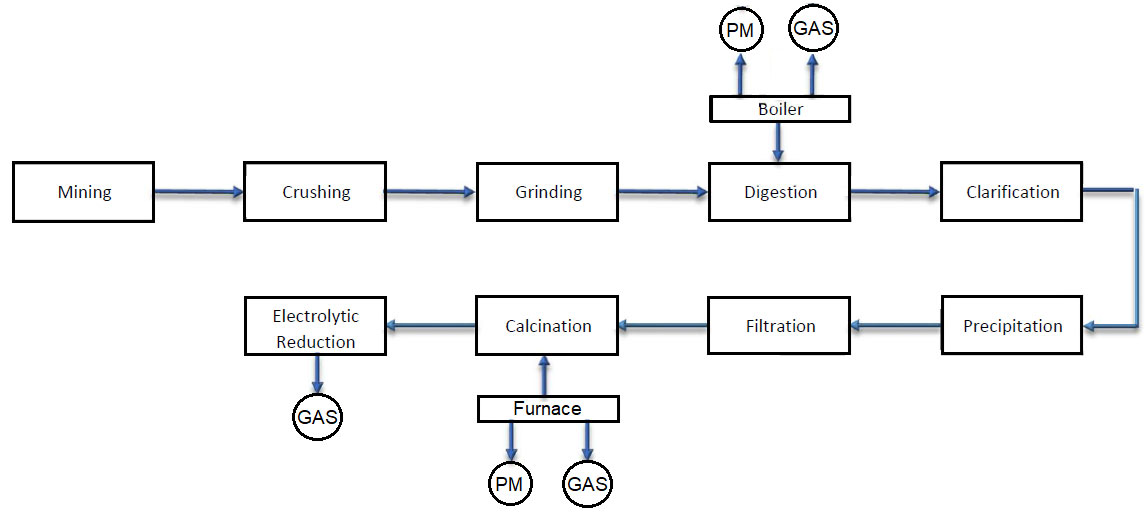

Gas emissions in the production of primary aluminium come from processes such as Digestion where A hot caustic soda (NaOH) solution is used to dissolve the aluminium-bearing minerals in the bauxite to form a sodium aluminate supersaturated solution. Steam generated from boiler is used for heating. At boiler stack emission gas are measured. Other process is calcination where gibbsite crystals are roasted at temperatures of up to 1100°C to drive off free moisture and chemically-connected water, producing alumina solids. Normally Furnace or Kiln are used for heating the crystals. At furnace or kiln emission gas are measured.

In Smelting (Electrolytic Reduction) process CO2 gas is emitted as carbon reacts with oxygen present in Alumina.